AFM heads on tracked base machines

Tracked harvesters and modiefied excavators are widely used in the forest.

Having strong construction and less electronic components they are easy to use and maintain.Tracked harvesters have strong boom configuration which is an advantage in clearcuttings especially when felling and processing big trees. Due to their power and strong boom tracked harvester are very efficient machines for working e.g. in windstorm damaged areas.

Tracked harvesters and modiefied excavators are widely used in the forest. Having strong construction and less electronic components they are easier to use and maintain.

Tracked harvesters have strong boom configuration which is an advantage in clearcuttings especially when felling and processing big trees. Due to their power and strong boom tracked harvester are very efficient machines for working in windstorm damaged areas.

Another important advantage of tracked harvesters is their ability to work on slopes. Tracked harvesters have better stability and climbing capacity in steep conditions due to a higher traction. Thanks to cabin leveling system on some of the tracked harvesters the driver constantly remains on a horizontal seating position regardless the slope.

The excavator based harvester is a multi-functional and economical alternative for harvesting purposes

The fitting of harvester heads to excavator bases is standard practice for AFM-Forest. AFM-Forest Ltd has developed special harvester heads for excavators. They adapt very well on excavators because of both their reliable hydraulic-contro system and a strong body structure. These machines are quite often just as sophisticated and capable as purpose built machines, but cost only a fraction of the price.

AFM harvester heads can be easily installed on a modern track-based hydraulic excavator between 10-40 tons weight with some modifications and extra protections for forest use. AFM is a well proven solution for easy and inexpensive transformation of your excavator into an efficient harvester or processor.

The power and productivity on the hills

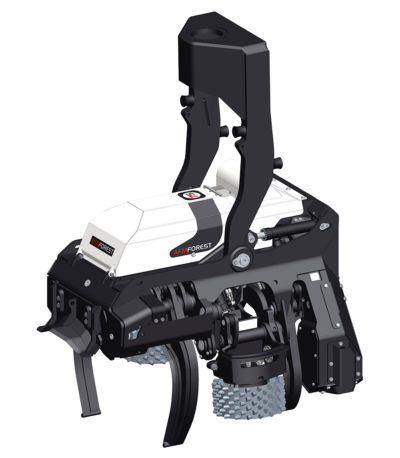

AFM brings the power and productivity on the hills! Three synchronized feeding rollers ensure high feeding force, secure non-slipping grip and low friction with stem. The strong grip of AFM heads makes it possible to pull heavy stems with the crane. High feeding force combined with optimal geometry of delimbing knives ensure accurate, fast and precise harvesting of heavily limbed wood and the most crooked stems.

AFM offers harvester heads originally designed to work on tracked harvesters and excavator bases. The frame of AFM heads is manufactured from high-strength steel, and as against heads of other manufacturers, it is monolithic which makes it highly durable and suitable for rough work on track based machines. Even after several years of use AFM heads remain highly productive. AFM harvester heads proved their reliability on hundreds of tracked machines.

Recommended products: